A benefit for multiple industries

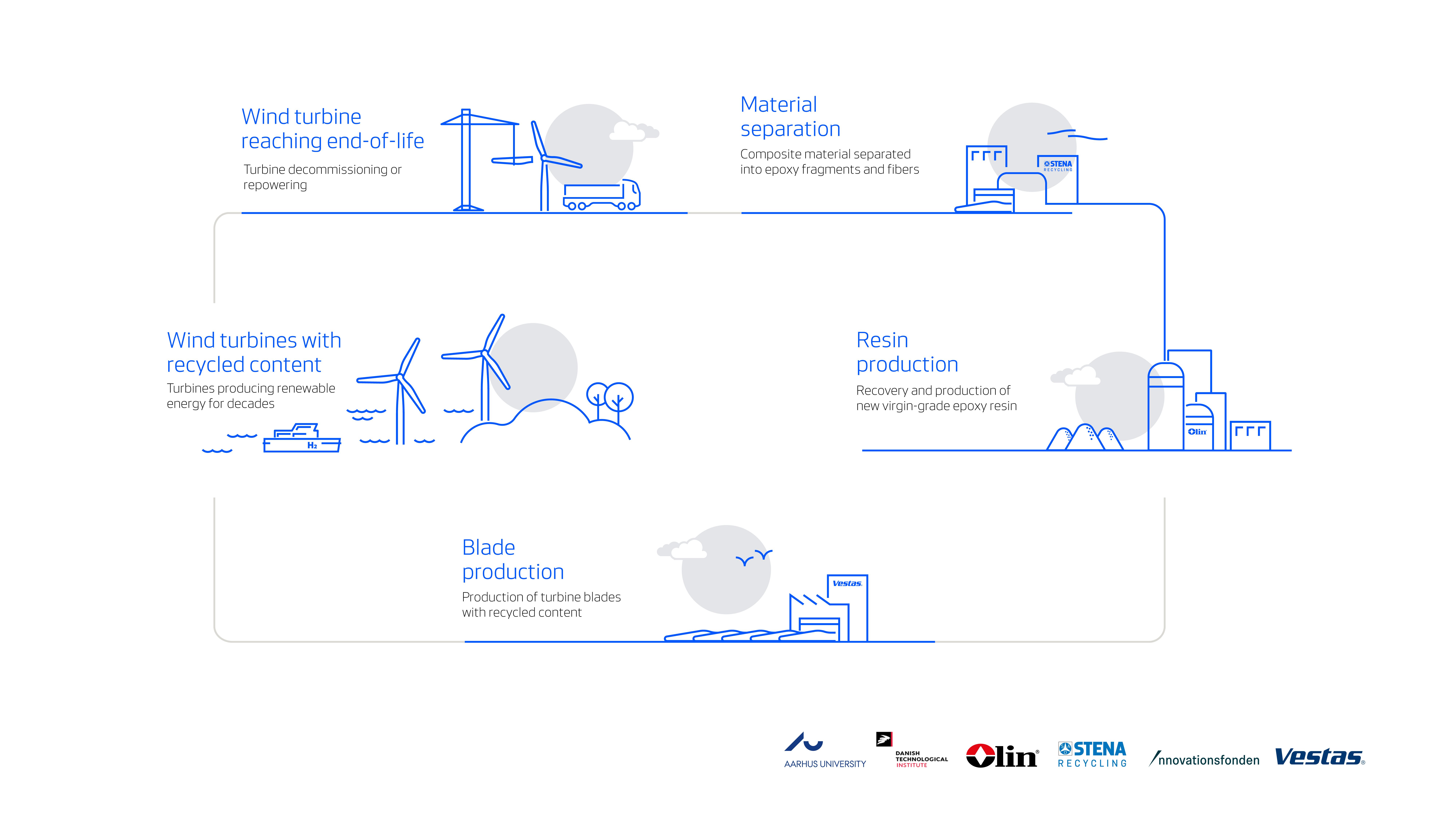

When the process is fully developed, it will not only enable the production of new wind turbine blades from recycled materials but also signal the potential to transform other epoxy-based composite materials into raw materials for a wider range of industries.

“We are already well underway and look forward to working on this pilot project in the coming period. By leveraging our extensive experience and infrastructure, we will help promote recycling so that together we can create a world where resources circulate instead of ending up in landfills”, adds Henrik Grand Petersen.